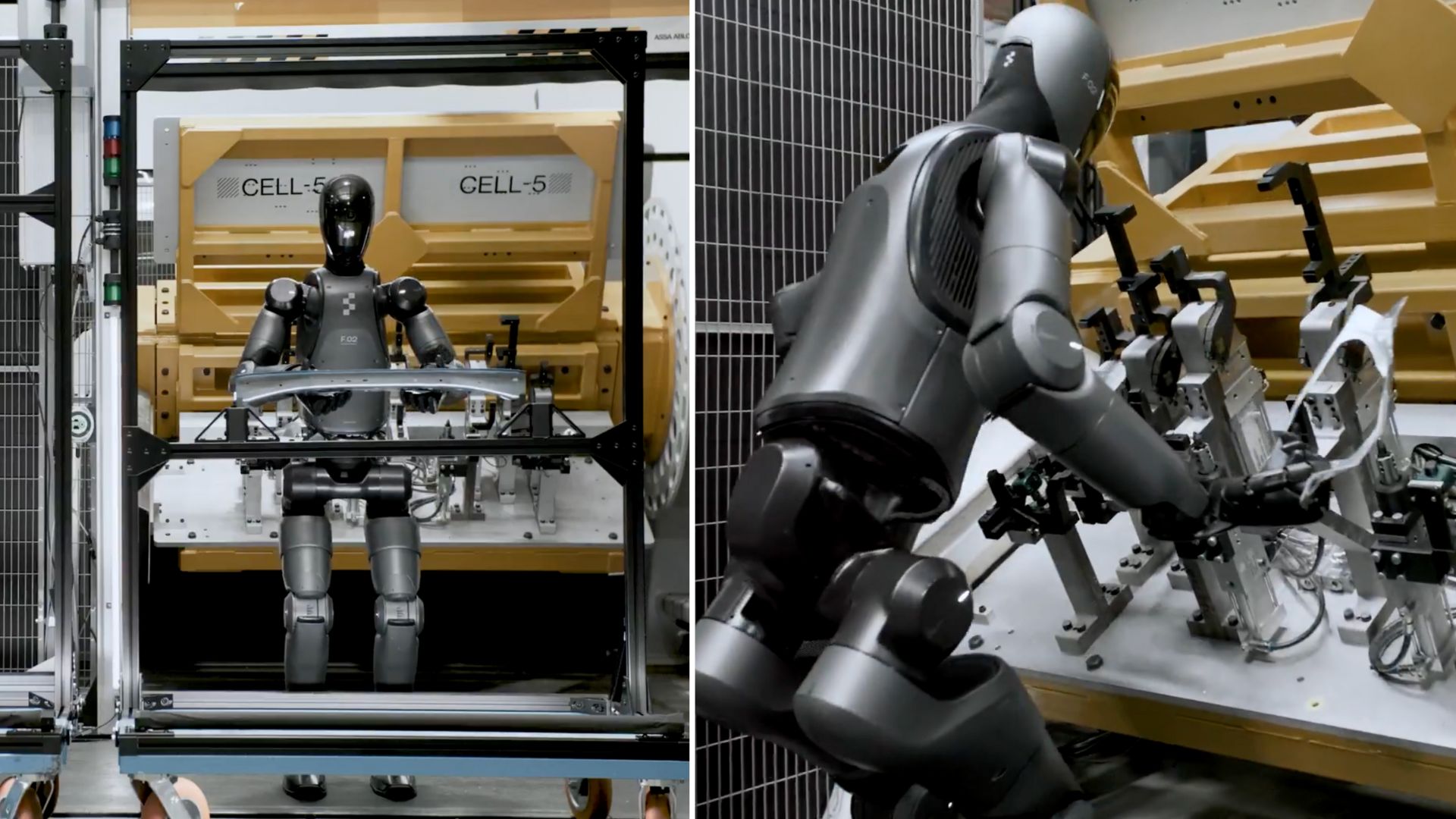

Figure AI, a robotics innovator, and BMW, the German automobile giant, have revealed remarkable advancements in the Figure 02 humanoid robot’s capabilities.

Operating on a production line, the Figure 02 robot has made a significant leap, achieving a 400% increase in speed and a sevenfold improvement in success rate.

I don’t understand the desire to make humanoid robots. If a human shape is more efficient because of the workflow or physical restrictions, why not just rearrange the production line and use regular robot arms?

I think it’s to provide a general solution for most labor shortages and not specific solutions.

The main use of humanoid robots is to work in environments suitable for humans (think inspecting a dam or such, climbing ladders and everything), as well as flexibility, especially when it comes to low-frequency tasks. BMW makes a lot of different models with tons of different options, their production line isn’t really a line it’s a directed graph.

It’s so that our replacements can work alongside us just long enough for us to trust them. It’ll make us less resistant when they drag us to the bio-repurposing vats.

mmm unexplained vats mmmm

Humans made things for humans.

Rearranging everything is better but more expensive. Sometimes it absolutely will be and has been done. There will be cases where humanoid robot is cheaper and easier. That’s not even bringing up new uses like waiter or carer, but those will be much later generations.